WP02 Transformer Project

The main goal of WP2 is to develop products that ensure high levels of maturity and industrial validation, focusing on the SISTRADE PLM Platform for Product Lifecycle Management as a pivotal outcome.

The main goal of WP2 is to develop products that ensure high levels of maturity and industrial validation, focusing on the SISTRADE PLM Platform for Product Lifecycle Management as a pivotal outcome.

This platform, starting at TRL6 and aiming to reach TRL8, integrates methodologies such as LeanDfX and 0-4D and is being validated in real industrial environments. The involved entities include:

• Research & Development Entities (ENESII): INEGI (WP Coordinator), INESC TEC, IST, IPCB, CATIM, and CENTIMFE.

• Technology Suppliers: SISTRADE, CEI and JPM.

• Demonstrator Companies: CEI, JPM, Vista Alegre, and Pereira & Ladeira.

The SISTRADE PLM platform introduces innovative solutions for managing complex product lifecycles while supporting Industry 4.0's extensive digitalization principles. The platform consists of 11 modules, including:

1. Dashboard and Administration: Personalized information and settings.

2. Project Management: Managing project lifecycles.

3. Competency Management: Tracking resource-related competencies.

4. Document Management: Centralized management of documentation and versions.

5. Idea Management: Innovation management module.

6. Unified Messaging Platform: Real-time communication.

7. Product Portfolio Management: Handling sub-product trees.

8. Engineering Change Order: Managing product change requests.

9. Digital Thread: Tracing processes and activities.

10. Requirements & Specifications: Digitizing product requirements with traceability.

11. LeanDfX: Optimizing product components across domains during design.

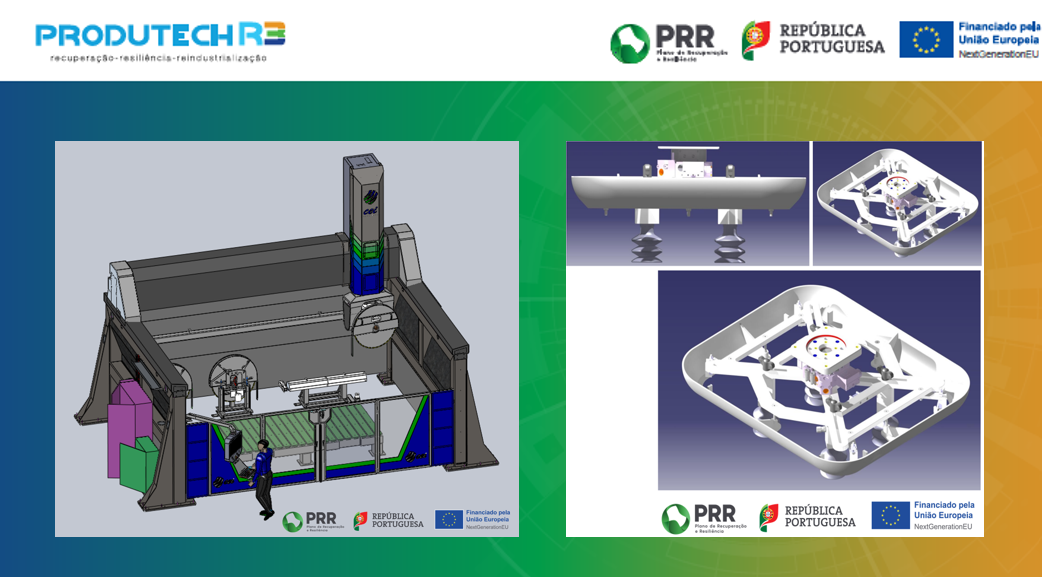

Two companies, CEI and JPM, are demonstrating the platform in industrial contexts for equipment development in ornamental rock processing and collaborative palletizing. Regarding progress and key developments, in the first phase, SISTRADE focused on developing new modules, Requirements & Specifications and LeanDfX, while refining existing ones. ENESII supported these developments by researching new methodologies, particularly in automation, additive manufacturing, emotional response, and circularity. INEGI organized two workshops focusing on the functionality of the PLM platform and the LeanDfX module. Demonstrator companies have since begun testing, with special focus on the Requirements & Specifications and LeanDfX modules. SISTRADE have been since integrating improvements to the platform, based on the demonstrator’s feedback. In parallel, ENESII’s are applying Design-for-X methodologies to support demonstrator companies in developing their equipment.

CENTIMFE applied DfAdditive Manufacturing on the development of a Griiper for JPM collaborative palletizer, while CATIM implemented DfSafety. Regarding CEI, INEGI focuses on the Df-Structural Integrity and Df-Circularity of a stone cutting machine, while IST is applying Df-Cost. To improve data collection and monitorization of the equipment, IPCB is working on Df-Edge Servicing and Df-Automation. Vista Alegre and IST are working together to develop novel packaging with a second-life concept. INEGI is implementing DfER methodologies to align product requirements with emotional responses, with completion targeted at the end of 2025. This integrated approach ensures that the project aligns with innovation, sustainability, and emotional design to drive industrial transformation and product lifecycle efficiency.